产品导航

Products

联系我们Contact Us

宜兴市锅炉辅机仪表厂

江苏东宝热能科技有限公司 联系人:林先生

手机: 13901535072

电话: 0510-87395588

传真: 0510-87391072

信箱: lxf807@126.com

地址: 宜兴市张渚镇善卷洞南侧

翅片管生产工艺介绍

|

|

1. 开卷装置Uncoiler

此装置是给焊接机器上料的,即连续提供翅片。每台焊接机器配备2个开卷装置。

This device is for loading and supplying fin to main machine continuously by 2 sets of unsolders.

a 最大翅片卷外径:1200mm ~ 1800mm

Maximum coil OD

b 用户方需准备的翅片卷内径:300mm

Required fin coil ID: 300mm

|

|||||||||||||||||||||

|

全自动翅片料件库 |

||||||||||||||||||||||

|

|

2. 全自动翅片料件库

Accumulator (Automatic system)

此系统可连续进行翅片进给,以焊接到管子上,无需机器中途停下。此装置在给机器供给翅片的过程中,可自动转换1号翅片卷和2号翅片卷;而且,通过张力控制装置,它还可控制翅片的张力,从而实现翅片的连续供给。

This system is for continuous fin feeding so to weld tube without machine stop. It supplies fin to main machine during coil exchanging process between 1st and 2nd fin coiler automatically and it controls the tension of by tension controller so to get constant feeding of fin to the machine.

|

|||||||||||||||||||||

|

开齿机及浮动辊 (全自动系统) |

||||||||||||||||||||||

|

|

3. 开齿机及浮动辊 (全自动系统)

Serrate & Dancer (Automatic system)

开齿机将翅片切开,可生产出锯齿形翅片管。剪切速度,根据辊子输送管子后焊接的速度自动控制。

There are fin cutting devices to produce serrated fin tube and cutting speed is controlled automatically depend on welding speed of tube dancer.

|

|||||||||||||||||||||

|

砂带送管装置(管子表面抛光装置) |

||||||||||||||||||||||

|

|

4. 砂带送管装置(管子表面抛光装置)

Belt Sander (Tube surface polish equipment)

焊接之前的管子打磨系统,可清洁管子,提高焊接品质

This the tube sanding system for cleaning tubes before welding process to improve welding quality

** 用户方须为每条生产线配备输除尘输送管道及除尘器,要求为:

The buyer shall prepare the dust collector according to following requirements:

风速: 25㎥/min 电机功率: 1.5kw 压力: 230mmAq

Speed: 25m3/min Power: 1.5KW Pressure: 230mmAq

|

|||||||||||||||||||||

|

牵引小车装置 |

||||||||||||||||||||||

|

|

5. 牵引小车装置 Pulling Carriage Unit

此装置为翅片间距装置。翅片间距根据管子的旋转速度确定,可连续保持稳定的间距、同时也可实现高速送管。此装置可更精确地调整及实现翅片的间距。同时,相比推进方式,此牵引方式可生产大尺寸的翅片管,故障停机率少一些,更易于操作。

This is the fin pitch driving device depend on tube rotation speed and the pitch rate against rotation speed is constant and high speed driving is possible. It is easy to adjust and divide the pitch precisely.

It is also possible to handle big size tube comparing with pushing type and has less NG rate and easy to operate.

|

|||||||||||||||||||||

|

输入传送装置 |

||||||||||||||||||||||

|

|

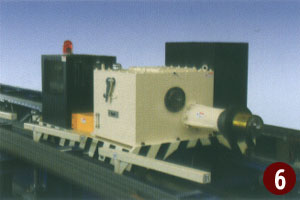

6. 输入传送装置 Inlet conveyor

此装置为连续焊接供管的送管装置,把新管子连接到正在焊接的管子端头。

It is an automatic tube feeding device for continuous tube welding by connecting mew to the end of existing tube.

|

|||||||||||||||||||||

|

输出传送装置 |

||||||||||||||||||||||

|

|

7. 输出传送装置 Outlet conveyor

此装置在翅片焊接过程中为翅片管的导出装置,即将焊接好后的翅片管传送出来,而机器不用停机。

It is device for guiding fin tube that is in fining process. It transfer welded fin tube to outside without machine stop.

|

|||||||||||||||||||||

|

焊接系统 |

||||||||||||||||||||||

|

|

8. 焊接系统 Welding part

通过此焊接系统把翅片焊接到管子上。系统由翅片管冷却喷嘴、高频输出变压器、调节变压器位置的上下工作台、翅片导轨滚轮、送管刹车滚轮等稳定及坚固地系统组成。

汽缸推动挤压辊,然后挤压辊推动翅片,使翅片更容易、更高效地环绕并焊接到管子上。同时也安装了火花探测装置,如发生翅片断裂情况,管子在旋转过程中能及时停止,因此,可有效减少管子损伤,减小变压器的输出。

It is the system for welding fin with tube and consist of cooling nozzle for fin tube, high frequency output transformer, un & down table for adjusting the position of transformer, fin guide roller and tube break roller with strong and stable systems.

Guide roller that is easy to connect and change fin with tube is air cylinder type for more efficiency, there is a spark detector is installed for rapid stop rotating tube in case of fin break so to minimize and prevent breakage of tube and output transformer.

|

|||||||||||||||||||||

|

操作装置及热感应匹配变压器装置 |

||||||||||||||||||||||

|

|

9. 操作装置及热感应匹配变压器装置 Operation unit & induction matching trans unit

|

|||||||||||||||||||||

| 高频感应电焊机 | ||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||

生产设备加工流程图

上一篇:翅片管/鳍片管

下一篇:高频焊接螺旋翅片管

网站二维码

网站二维码